I agree,

adjusting the valves on the GSF400 is easier than my EX250. Access to the valves is better, you can clearly see what you're doing. I really enjoyed the process of setting the Bandit's valves.

When I started work I accidentally had the Service Manual open to the 1991-1992 model valve clearance specification, because the '91-'92 specs are printed right in Chapter 2 "Periodic Maintenance and Tune-Up Procedures". After working on the first couple of valves I suddenly remembered that I should look in the back of the Service Manual, where the '93 "GSF400P" Service Manual Supplement is located, to find the '93 specification.

'91-'92 Spec: IN-.10mm-.15mm, EX-.15mm-.20mm

'93 Spec: IN-.13mm-.18mm, EX-.20mm-.25mm

(quite a difference. the '93 makes less horsepower, right? 54hp vs 59hp I think?)

The difficult part, as people have mentioned, is getting everything removed; fuel tank, coolant, radiator, cooling plumbing, thermostat housing, valve cover. My Bandit is worse to disassemble because there's a lot of extra wiring that passes over the top of the valve cover.

While I had the valve cover off I did a few other things:

1. inspected and measured the Cam Chain (across multiple pitches of 20). The service limit is 143mm for any 20 pitch length of it. I came up with right at 141mm on every measurement.

2. carried out the "Cylinder Head Nuts and Exhaust Pipe Bolts" loosening and re-torquing procedure (recommend every 6000Km in Chapter 2 of the Service Manual).

3. replaced all of the old gaskets (valve cover gasket, valve cover bolt gaskets, valve cover breather o-rings and gasket) with new ones.

4. Inspected the Spark Plugs, all four plugs looked great, nothing abnormal in color or wear, no electrode erosion.

I was happy to find that everything in the valve train looks great. Very little sign of wear, nothing abnormal. It seems that this engine has never been allowed to run low on oil.

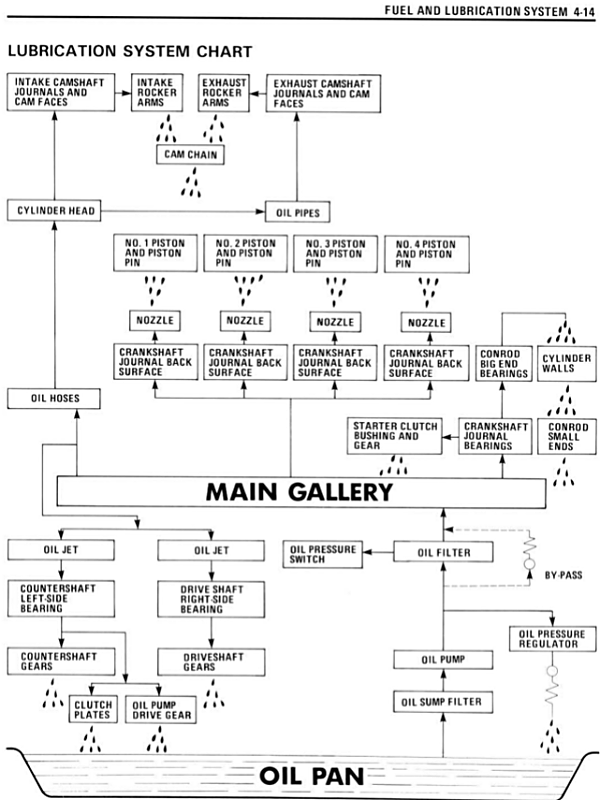

I believe a large part of the credit for this healthy engine goes to the large oil capacity of the GSF400. 3.2 liters (total capacity) for a 400cc engine? That's a lot of oil for such a small motor. Also, I'm very impressed with the GSF400's oil system, which is very advanced for a 1990 Sport-level motorcycle engine.

Have you ever looked at the oil delivery schematic in the Service Manual? It's a thing of beauty!!

(There's even an oil jet squirting onto the underside of each piston... Wow, just wow.)

I ended up spending the whole day in the garage, enjoying the work, appreciating the engineering/design of the engine. It was dark when I finally put the bike back together.

Rode it this morning, everything's perfect. Very Happy.