The more video's the better, in my opinion

Thanks, I appreciate your vote in favor of more videos (and photos).

Just some things I noticed from video's: (you probably know this but still).

- 12.00V is pretty low for a battery.

Yes, you're right, the battery is probably nearing the end of its useful lifespan. The battery came with the bike when I bought it and like the rest of the bike the battery's history is unknown to me. I'm trying my best to preserve this battery well enough to get through the building and testing phase of the project, I don't know if you noticed but I've been using a large farm-tractor battery and jumper cables to supplement the Bandit's battery for stationary testing. Doing this has allowed me to do the type of testing that requires multiple extended cranking/starting-stopping of the Bandit's engine without flatting the Bandit's battery. When the work is all done and the project is 99% complete I'll treat the Bandit 400 to a nice new battery.

- What makes you say it needs more air at start? The more choke I use at start, the higher the RPM gets to initially. It shoots right up to 2000rpm. Without choke, it starts like how it was on your video.

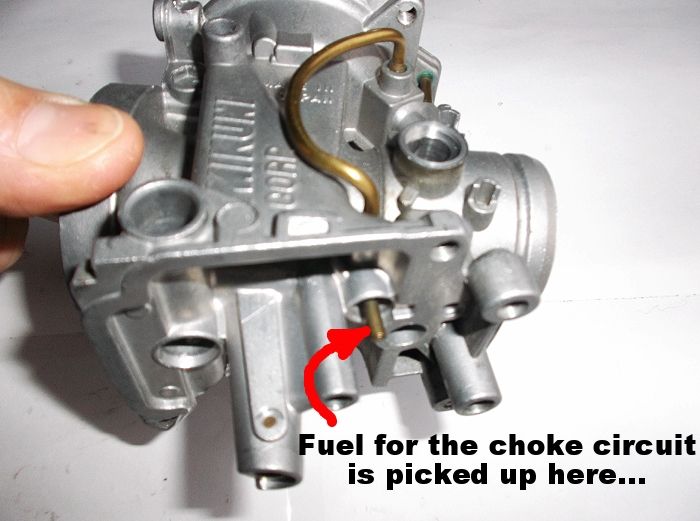

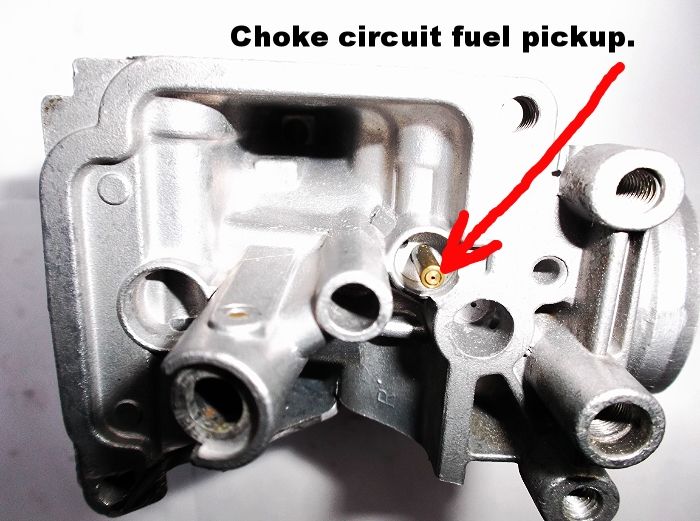

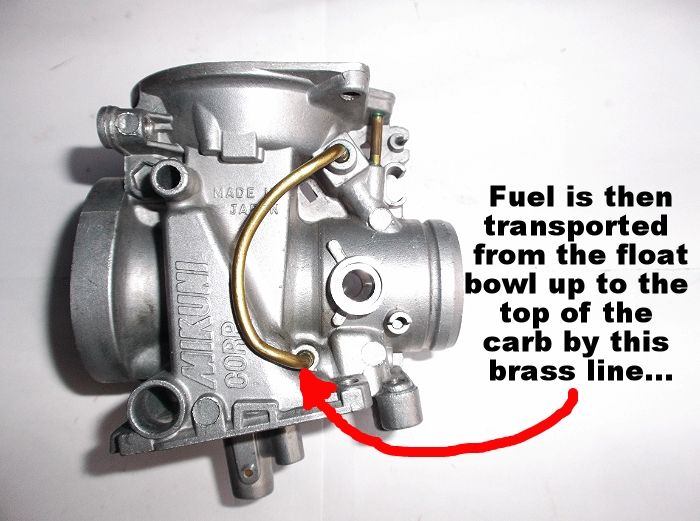

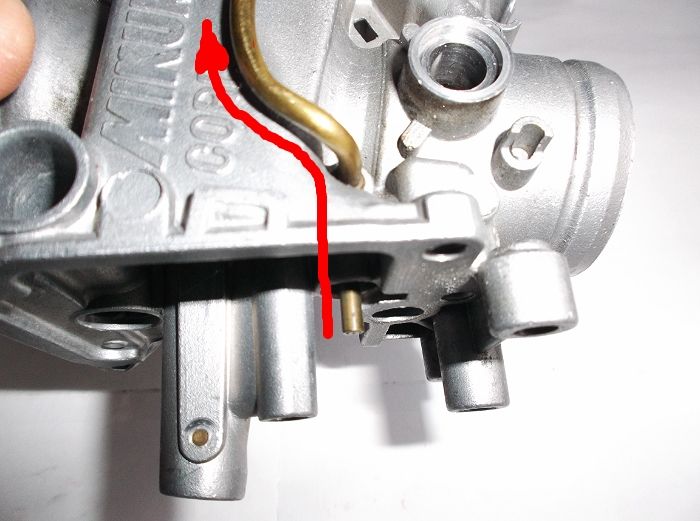

It sounds like you might not be totally familiar with the layout of the Mikuni BST33 slingshot carburetor, especially its Choke circuit.

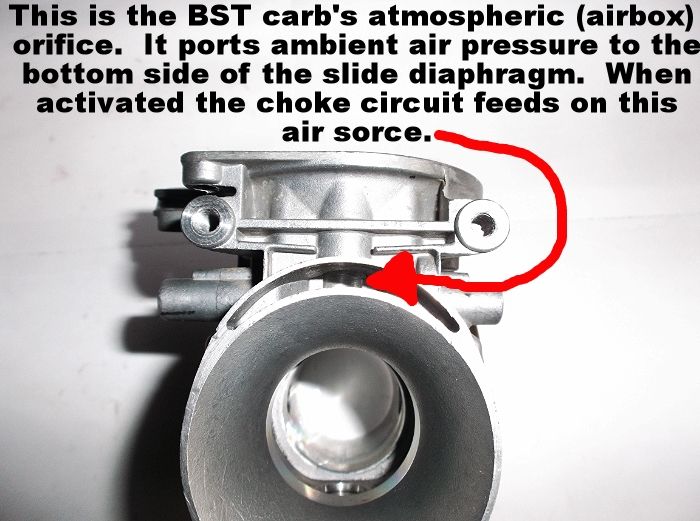

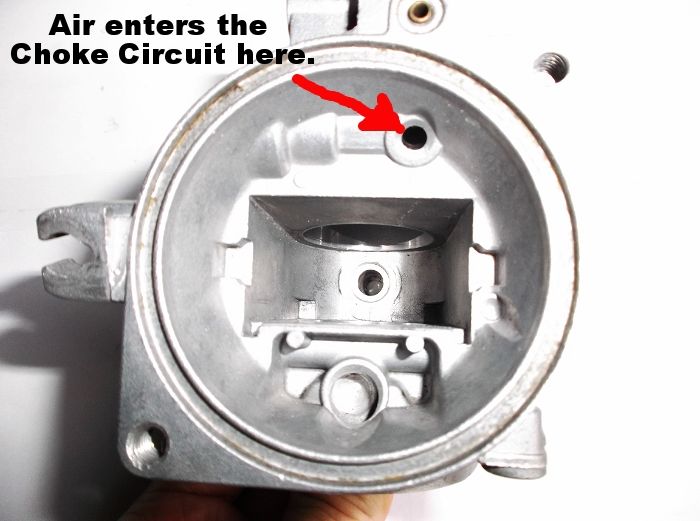

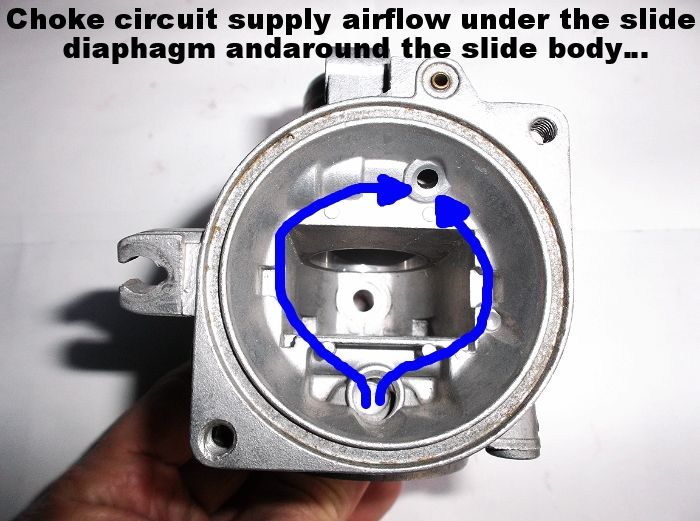

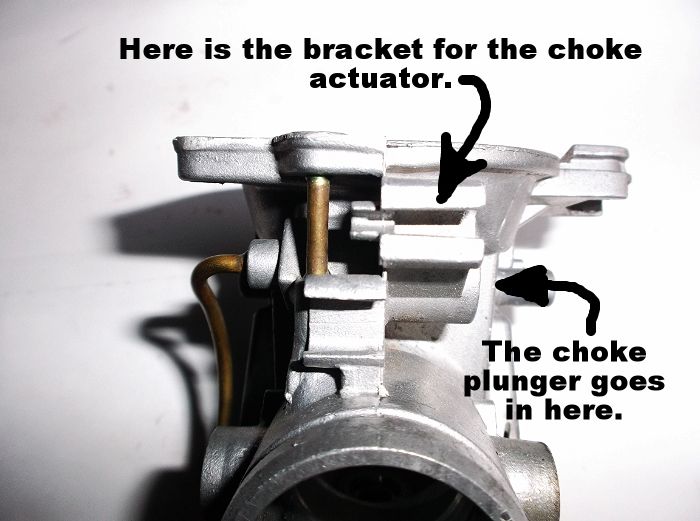

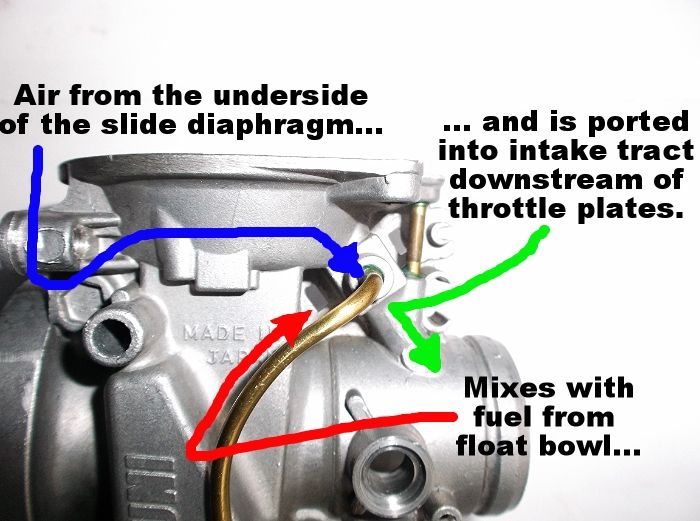

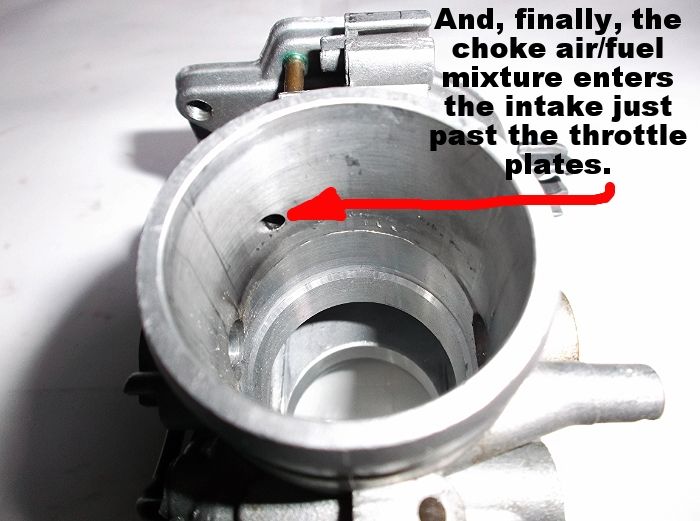

The BST33 carb mixes BOTH air and fuel in its choke circuit. Let me walk you through the choke circuit of a stock, original Mikuni BST32 (which is exactly the same as the BST33 except for the size of its bore)...

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

- Are you running without exhaust silencer? It sounds like at that at low rpm or like you have a leak on the exhaust.

My Bandit's exhaust system is an aftermarket Yoshimura "4 into 2 into 1" style header and the exhaust canister is also a Yoshimura. The canister is free-flowing, it doesn't have an add-on silencer. The Yoshimura header is of the type designed to maximize scavenging/flow at mid-range power/torque, in its first two "Y"s it combines cylinders #1 and #4 together and cylinders #2 and #3 together. Then it combines these two at its second "Y".

I had the header sand-blasted and ceramic coated so it looks nice but the canister is still in its original (to me) state which is very dented and scraped up. There are no leaks in the system. If the exhaust note sounds odd on the video I'd guess it's because the sound is bounding around in my small garage.

- Why was it increasing RPM because the coolant was hot? Doesn't make sense to me.

Okay, maybe my word choice on the video was a bit confusing. When I say, "because the coolant temperature is rising" on the video I'm really thinking, "because the temperature of the metal, plastic and rubber in the Bandit's intake tract is rising". (Obviously there are other parameters to consider; for example, the temperature of the oil affects how it flows. Cold oil is a drag on the system that has to be compensated for.)

Starting an engine from dead cold is a complex, dynamic situation.

When you start up from dead cold the metal and any other substances, like plastic or rubber used in the walls of the intake tract (carbs, connector boots and the cylinder head) are cold and the intake fuel vapor readily adheres to them. Because of this the cold startup cycle (from dead-cold to warmed up to normal operating temperature) is a highly dynamic, constantly changing set of parameters.

In modern fuel injection systems the engineers who design them actually take into account the amount of fuel that can/will adhere to the metal in the intake tract. They take everything into account: the temperature, the amount of metal, the metal's thermal characteristics, the amount of fuel being injected, the volume of air being moved. And they come up with a formula that contains variables that account for both "fuel that adheres to walls" and "fuel that is sucked from walls".

This necessitates a very carefully choreographed fueling scheme to achieve smooth RPM control during a fuel injected startup. When the enormous computational ability of a human brain is placed in charge of a Choke lever during cold startup this complexity is easily handled, almost as an afterthought. But when you're programming a computer to do it you have to be very elementary about it. Coolant temperature is the parameter we use to estimate the heat-state of the intake tract.

Obviously, as the temperature rises these two variables ("adheres to walls" and "sucked from walls") are in a constant state of change which means the air/fuel ratio is also going to constantly change. In the early part of the start, when things are at their coldest the "adheres to walls" factor is the biggest, but as the temperature of the intake tract rises toward normal operating temperature the "sucked from walls" factor becomes the biggest factor.

When normal sustained operating temperature is reached the two reach and maintain an almost balanced state, except during rapid throttle changes.